Choose Your Tube Furnace Here

-

Horizontal Tube Furnace

View Products+

-

Vertical Tube Furnace

View Products+

-

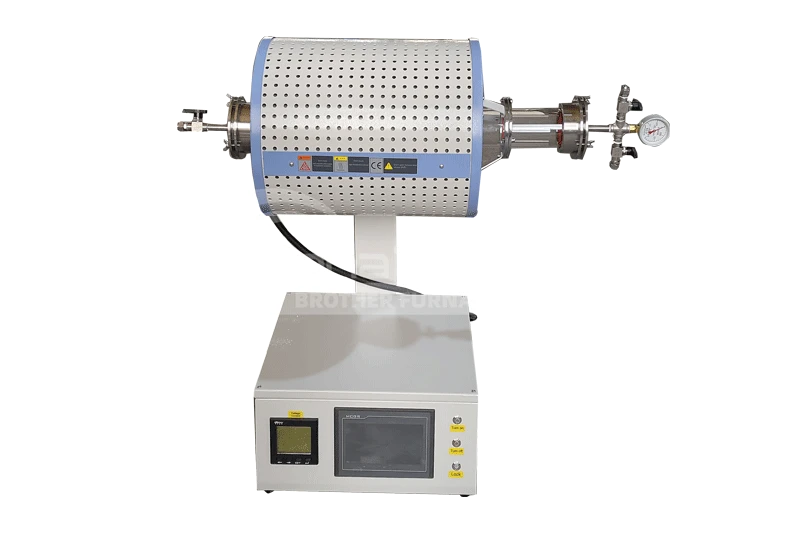

Rotary Tube Furnace

View Products+

-

Slide-Rapid Cooling Tube Furnace

View Products+

-

Vacuum Tube Furnace

View Products+

-

Laboratory Multi-Station Tube Furnace

View Products+

-

Steam Activation Tubular Furnace

View Products+

-

CVD/PECVD Tube Furnace

View Products+

-

(Double/three/five temperature zones)Multi-Temperature Zone Tube Furnace

View Products+

-

Double-Tube Tube Furnace

View Products+

-

Customized Tube Furnace

View Products+

-

Sliding Track Atmosphere Tube Furnace

View Products+

Leave message now!

Tube Furnace Soulution Examples

Material Category | Typical Processing Technology | Applicable Structure | Temperature Range |

|---|---|---|---|

Metal Materials | high-temperature resistance | Semiconductor Silicon-Based Chemical Vapor Deposition | 800℃ – 1600℃ |

Ceramic Materials | Acid/alkali resistance | Gradient Sintering of Cemented Carbide | 1200℃ – 1600℃ |

Semiconductor Materials | Ultra-low thermal expansion | Wafer Phosphorus Diffusion | 600℃ – 1300℃ |

Nanomaterials | Nanoparticle Synthesis, Carbon Nanotube Growth | Horizontal/Rotation | 500℃ – 1200℃ |

Polymer Materials | Carbonization, Graphitization, Pyrolysis | Horizontal/Multiple Temperature Zones | 800℃ – 1600℃ |

Glass Materials | Melting, Annealing, Crystallization | Horizontal/Vertical | 1000℃ – 1500℃ |

Powder Materials | Calcination, Activation, Solid-State Reaction | Rotation/Multiple Temperature Zones | 500℃ – 1400℃ |

20-Year Vacuum Furnace Manufacturer - Brother Furnace

-

Strong R&D Capability

Continuous innovation and technological advancement

-

Reliable After-Sales Support

Comprehensive service and technical assistance

-

Professional Solutions

Tailored to diverse heat treatment needs

-

Efficient Supply

Timely delivery with quality assurance

-

Extensive Industry Experience

Trusted by global customers across various

Brother Furnace's Qualification Certificate

Advantages of Brother Furnace Tube Furnace

● High-Temperature Stability:

1℃ temperature control accuracy with stable operation up to 1700℃, eliminating thermal drift issues common in conventional furnaces.

● Energy Efficiency:

Alumina fiber insulation design reduces heat loss by 30%, achieving lower energy consumption than comparable models.

● Intelligent Control:

One-touch programmable heating curves with multi-stage temperature profiles, streamlining R&D and production workflows.

● Contamination Prevention:

Double-layer sealing system + isolated gas channels to eliminate cross-contamination between samples.

● Thermal Shock Resistance:

Durable furnace tube materials (e.g., alumina tubes) withstand rapid thermal cycling, extending operational lifespan.