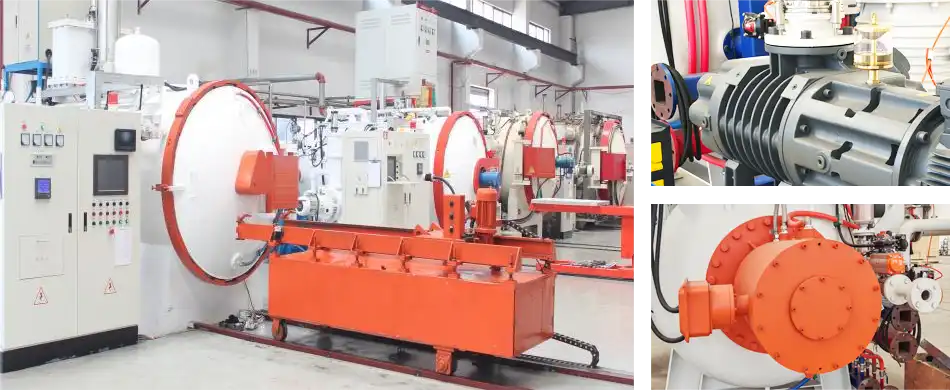

Choose Your Vacuum Quenching Furnace Here

-

Vacuum Gas Quenching Furnace

View Products+

-

Vacuum Double Chamber Oil Quenching Furnace

View Products+

Oil Quenching VS Gas Quenching

The two common types of vacuum quenching furnaces are vacuum gas quenching furnaces and vacuum oil quenching furnaces, with some key differences between them:

Vacuum Gas Quenching Furnace | Vacuum Oil Quenching Furnace | |

|---|---|---|

Cooling Medium | Uses gas (usually nitrogen or argon) as the cooling medium. The cooling process is gentler and more suitable for workpieces sensitive to deformation. | Utilizes special quenching oil for rapid cooling, ideal for workpieces requiring high hardness and wear resistance. |

Cooling Rate | Relatively slower cooling rate, mainly used for materials sensitive to temperature changes or requiring toughness. | The involvement of quenching oil, achieves faster cooling rates, enhancing workpiece hardness. |

Material Applicability | Suitable for various materials, including high-alloy and low-alloy steels, especially for workpieces with high oxidation requirements. | Particularly suitable for high-carbon steels and alloy steels, achieving higher strength and toughness. |

Cost and Operation | Often simpler in structure, lower operating costs, and easier maintenance. | Equipment is relatively complex, requiring more costs and operational management for oil maintenance and replacement. |

Quenched Workpiece

After undergoing the quenching process, the workpiece achieves enhanced hardness, durability, and resistance to wear, ensuring it performs at its best in demanding applications.

Brother Furnace's Strengths

- High-Quality Materials:The furnace body is made of high-temperature and shock-resistant materials, with high-performance heating elements such as molybdenum wire (Mo), tungsten wire (W), molybdenum disilicide rods (MoSi₂), and silicon carbide rods (SiC);

- Intelligent Production:Advanced CNC machining and precision manufacturing are employed to ensure the accuracy of the furnace structure and temperature control;

- Core Components:Equipped with high-performance heating elements, a precise temperature control system, and optimized atmosphere management;

- Strict Quality Testing:Comprehensive testing of key indicators, including temperature uniformity, vacuum sealing, and atmosphere stability;

- Safe and Reliable Transportation:Strict packaging inspection ensures no damage during transport.