Choose Your Precision Vacuum Brazing Solutions Here

-

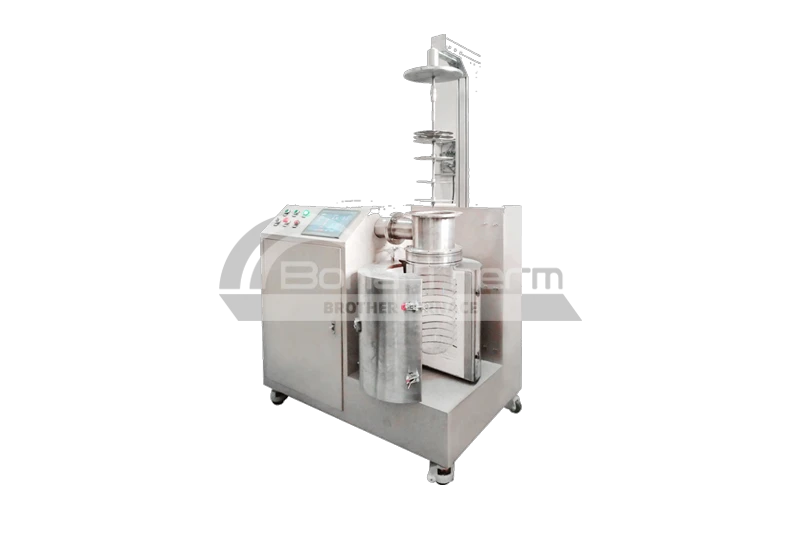

Vacuum Cutting-Tools Brazing Furnace

View Products+

-

Vacuum Brazing Furnace ( heat-resistant steel hot field )

View Products+

-

Vacuum Brazing Furnace ( molybdenum thermal field )

View Products+

-

Diamond Vacuum Brazing Furnace

View Products+

-

PCD and PCBN Vacuum Brazing Furnace

View Products+

-

Large High-Vacuum Brazing Furnace

View Products+

-

Vacuum Aluminum Brazing Furnace up 1500℃

View Products+

-

AI Liquid Cooling Plate Vacuum Brazing Furnace

View Products+

Detailed Display of Vacuum Brazing Furnace

|  |  |

Front of vacuum brazing furnace | Furnace Chamber Interior | Three-Color Warning Light |

|  |  |

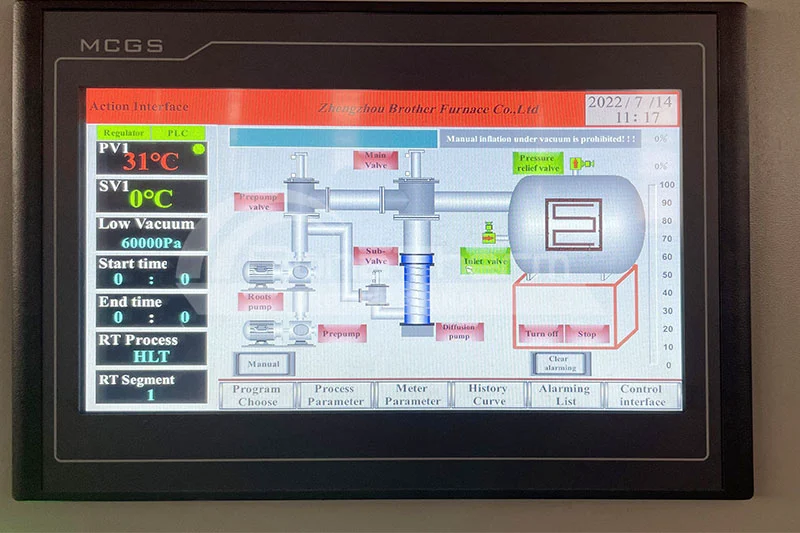

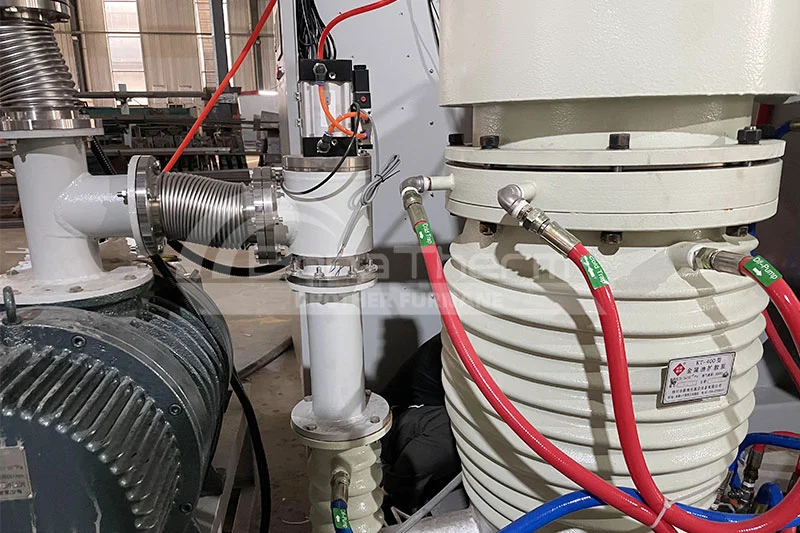

PLC Touch Screen Interface | PLC Touch Screen Interface | Vacuum Pump |

Precision Vacuum Brazing Solutions

Industry | Application Case Examples | Technical Highlights |

|---|---|---|

Aerospace | Turbine Blade Honeycomb Seal Structure Brazing | Achieving 0.05mm ultra-thin brazing seams, meeting AMS2750E high-temperature measurement standards. |

| Material: Nickel-based High-Temperature Alloy | |

Medical Devices | Titanium Alloy Artificial Joint Porous Surface Brazing | Ensuring biocompatibility, certified by ISO 13485 for medical equipment |

| Temperature Uniformity: ±1.2°C | |

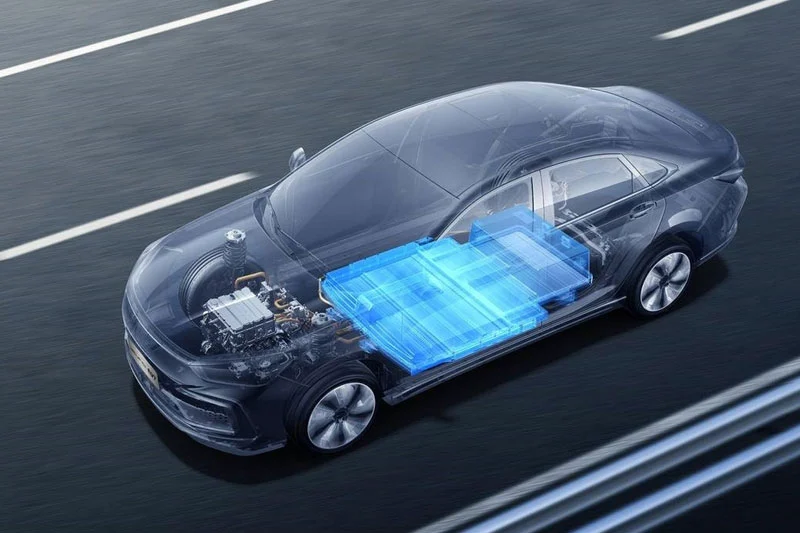

New Energy Vehicles | Silicon Carbide Power Module Copper Substrate Brazing | Gradient heating technology prevents ceramic cracking, supporting mass production of 800V high-voltage platforms. |

| Peak Temperature: 950°C ±1.5°C |

Brother Furnace's Qualification Certificate

Unique Advantages Of Vacuum Brazing Furnace

- An almost unlimited range of materials can beused (base materials and brazing alloys);

- Minor distortions due to an even furnaceheating;

- Very good joining quality due to the vacuumatmosphere;

- High strength, even at high operatingtemperatures;

- Avoidance of fluxes;

- High reproducibility due to excellenttemperature uniformity and comfortablecontrol of modern furnace systems, including the process documentation;

- Possibility of a combined heat treatment(brazing and hardening);

- Hardening and annealing can be integrated into the process;

- Low environmentalimpact.

Common Questions of Vacuum Brazing Furnace

-

What materials are suitable for vacuum brazing furnaces?

Suitable for brazing materials such as aluminum alloys, titanium alloys, stainless steel, and high-temperature alloys, especially in high-precision fields like aerospace, semiconductors, and automotive components.

-

How does vacuum level affect brazing quality?

Higher vacuum levels effectively remove oxide layers, ensuring that the brazed joint is free of porosity and contaminants, thus improving joint strength and sealing properties.

-

How is the heating and cooling rate controlled in the furnace?

The furnace features multi-stage temperature programming, with adjustable heating rates (e.g., 1-20°C/min). Cooling can be accelerated through a water cooling system or inert gas circulation, providing process flexibility.

-

Is the energy consumption of the brazing furnace high?

The furnace uses nano-grade insulation materials and high-efficiency heating elements, reducing energy consumption by 30-40% compared to traditional models, making it more economical for long-term use.

-

Can the furnace be customized for special sizes or functions?

Yes, we offer non-standard customization, including furnace chamber size, temperature zones, and gas line configurations, with delivery in as little as 15 days.

-

Is technical support available in a timely manner?

We provide 24/7 global technical support with a 4-hour response time for urgent issues, ensuring minimal disruption to your production.