Vacuum Brazing Furnace for AI Liquid Cooling Plate

The demand for efficient cooling systems in GPU servers and data centers is increasing, as high-power chips rely on the high-quality brazing and sealing performance of AI liquid cold plates for stable operation.

Brother Furnace AI Liquid Cold Plate Vacuum Brazing Furnace is specifically designed for AI servers, high-density data centers, and the 3C electronics industry, helping manufacturers achieve:

- High consistency and low leakage rate

- Stable batch production

- Optimized performance and lifespan of liquid cold plates

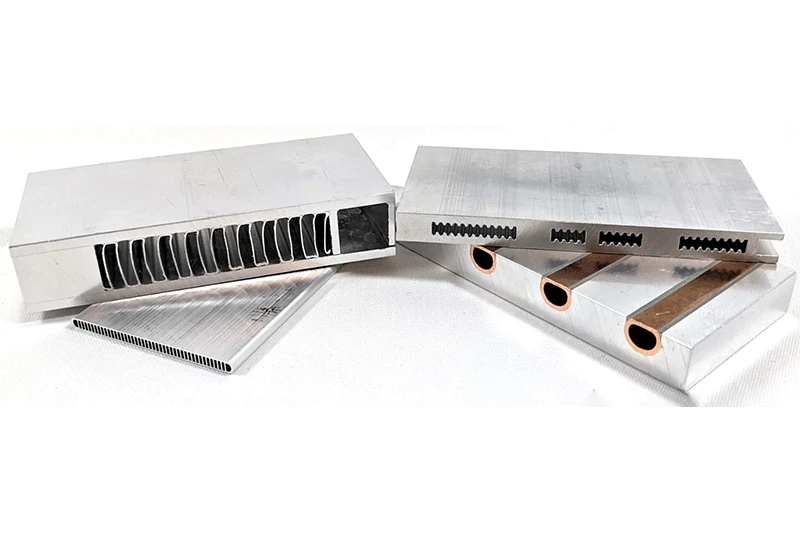

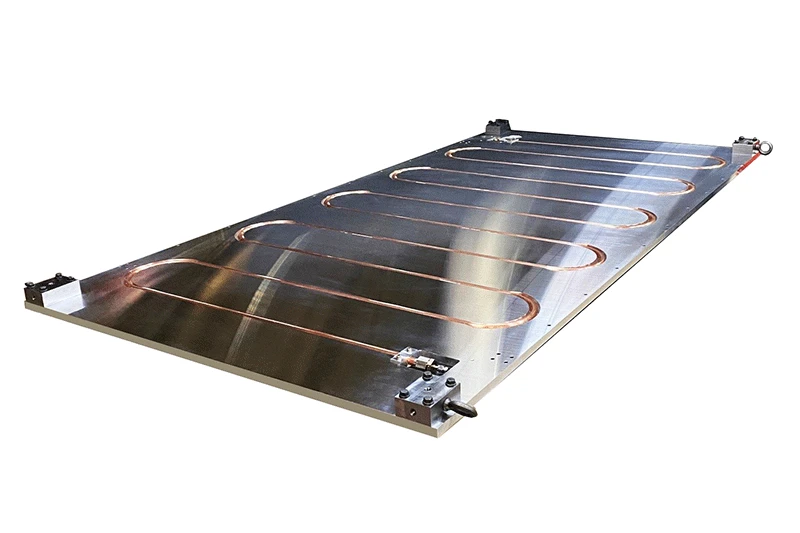

What is an AI Liquid Cold Plate?

An AI liquid cold plate is a core component for cooling high-power GPUs/CPUs. It dissipates chip heat through circulating coolant. Its welding quality and channel sealing performance directly affect cooling efficiency and service life.

|  |

The latest independent liquid cold plates demand high brazing temperatures (up to 1200°C or higher), smooth welding surfaces, extremely high sealing performance (≤1×10⁻⁶ Pa·m³/s, helium mass spectrometry leak detection), high shear strength (≥60MPa), pressure resistance (≥1.5MPa), and long thermal cycle lifespan. General vacuum brazing furnaces struggle to meet these stringent requirements.

To address these high-quality demands, our company has developed a dedicated AI Liquid Cold Plate Vacuum Brazing Furnace tailored for the AI and high-density data center industries.

Features

Brother Furnace AI Liquid Cold Plate Vacuum Brazing Furnace offers the following standout features:

- Maximum working temperature of 1350°C, meeting high-temperature vacuum brazing process requirements

- Multi-zone temperature control (at least 3 zones), with temperature uniformity of ±3°C (measured in segments from 500°C to 1250°C)

- Ultimate vacuum of 8×10⁻⁴ Pa, working vacuum of 4×10⁻⁴ Pa. The vacuum system employs a mechanical pump + Roots pump + diffusion pump/molecular pump, equipped with a dedicated start-up high valve and cold trap

- Pressure rise rate ≤0.3 Pa/h (after baking and degassing), minimizing welding defects

- Inert gas filling for rapid cooling, improving product performance and production efficiency

- Customized high-temperature alloy racks for secure part loading and large capacity

- Electrical components, instruments, and vacuum systems sourced from top international brands

Our AI liquid cold plate brazing furnace has been successfully deployed in leading AI and semiconductor companies, with the brazing quality of liquid cold tubes and connectors meeting customer satisfaction. This marks a technological breakthrough for BrotherFurnace in high-precision brazing and liquid cooling manufacturing, and we look forward to providing high-performance vacuum brazing equipment and technical solutions to more enterprises in AI, data centers, and 3C electronics.

Please feel free to contact us with any needs; Brother Furnace will provide professional solutions.

Typical Application Industries

- AI Server Manufacturing

- High-Density Data Centers

- Semiconductor Cooling Modules

- 3C Electronics

- High-Performance Computing (HPC)

AI Liquid Cold Plate Brazing Furnace Technical Parameters

Feature | Model: BR-QHM-669 | Model: BR-QHM-8812 |

|---|---|---|

Hot Zone Dimensions | 600 x 600 x 900 mm (W x H x D) | 800 x 800 x 1200 mm (W x H x D) |

Loading Capacity | 800 kg | 1800 kg |

Max. Operating Temp. | 1350 °C | |

Continuous Working Temp. | ≤ 1300 °C | |

Voltage & Rated Power | 380V, 3-Phase; Total Power: 230kW; Heating: 180kW; Rapid Cooling Fan: 15kW | |

Chamber Structure | Double-layer water-cooled shell. Inner: Mirror-polished SUS304 stainless steel; Outer: High-strength Q345 carbon steel. | |

Heating Zones | 3 Zones: Independent control for front door, rear door, and furnace body. | 4 Zones: Independent control for front door, rear door, and dual-section furnace body. |

Vacuum Level | Ultimate Vacuum: 8×10−4 Pa (empty, cold, decontaminated); Operating Vacuum: 4×10−3 Pa (Note: Subject to workpiece outgassing rate). | |

Pressure Rise Rate | ≤ 0.3 Pa/h (after thorough degassing) | |

Temperature Control Accuracy | ± 1 °C | |

Temperature Uniformity | ± 3 °C (Tested at 500, 700, 850, 1000, 1150, 1250 °C). Note: K-type sensors are used below 1000°C; thermal rings are used above 1000°C. | |

Heating Rate | 0–20 °C/min (Adjustable); Recommended: <10 °C/min (below 1000°C); <5 °C/min (1000–1300°C). | |

Rapid Cooling System | Nitrogen cooling, heat exchanger, power 15KW, pressure 2bar

| |

Thermocouples | Control: S-type (x1); Over-temperature Alarm: S-type (x1); Protection tube: 99.7% high-purity corundum. | |

Heating Elements & Hearth | High-temp Moly-Lanthanum (MoLa) alloy strips with reinforced double-crimped edges (anti-deformation). Insulation: 4 layers of High-temp Molybdenum (inner) + 4 layers of 310S Stainless Steel (outer). | |

Control System | •Controller: Eurotherm (UK), 0.1 grade high-precision control. • Programming: 50-segment PID programmable curves. • Power Regulator: Digital module with current limiting to prevent surges/tripping. • Output: Linear current output with phase-shift SCR triggering for precise temp. stability. • Components: Schneider, ABB, or equivalent tier-1 international brands. | |

HMI (Human Machine Interface) | 15-inch LCD touchscreen; 512MB RAM; Integrated Ethernet port; Supports wireless expansion and remote monitoring via Mobile APP. | |

Vacuum Pumping System | High-performance configuration: Mechanical Pump + Roots Pump + Diffusion Pump (Imported brands). Includes high-vacuum starting valves, cold traps, SUS304 piping, and digital composite vacuum gauges. | |

Gas Circuit | Single inlet and single outlet configuration; the overpressure solenoid valve opens automatically, with a parallel mechanical pressure relief valve installed as a backup safety protection. | |

Water Cooling System | Explosion-proof stainless steel piping; Integrated sensors for water pressure, flow rate, and temperature with audio-visual alarms. | |

Loading/Unloading | Automatic motorized loading trolley with customized workpiece racks. | |

Get Inquiry

Get Inquiry Send Email

Send Email