Introduction

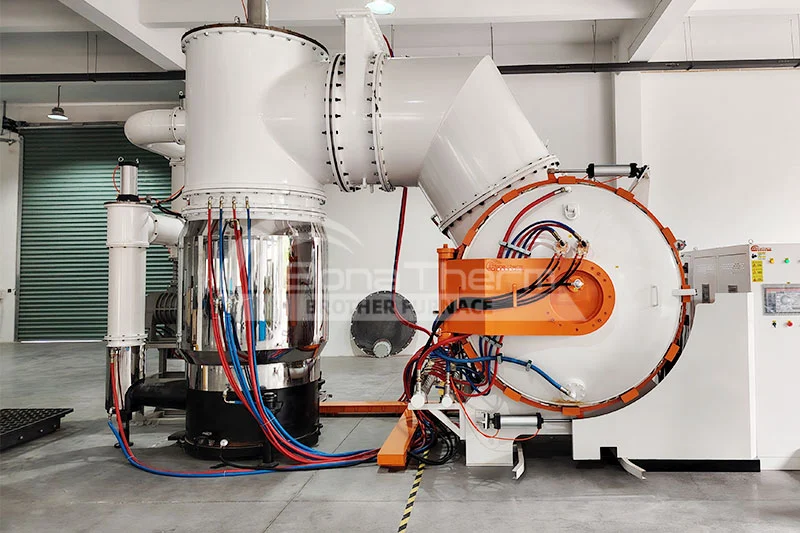

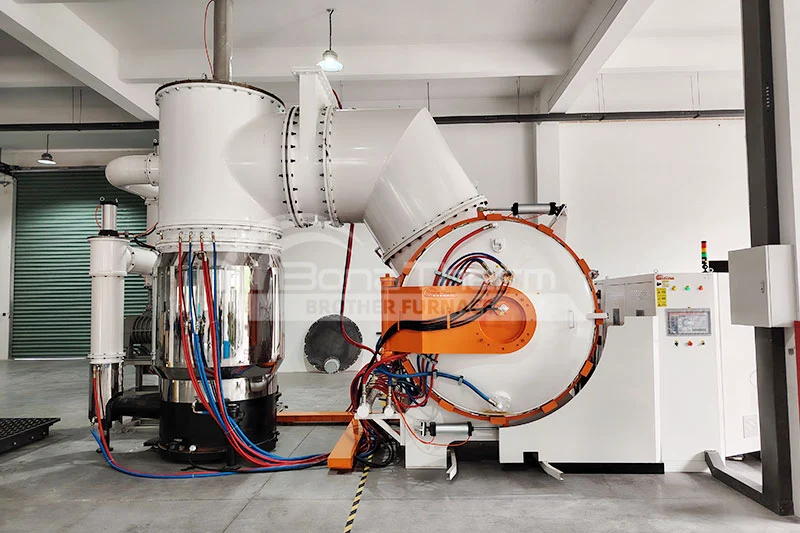

The Large High-Vacuum Brazing Furnace is engineered for demanding joining processes that require clean, stable, and precisely controlled vacuum conditions. Built with a durable stainless-steel chamber and high-efficiency heating elements, this system delivers consistent temperature performance, making it a reliable choice for high-precision manufacturing in aerospace, electronics, automotive engineering, and material research.

Application Fields

-

Precision brazing of aerospace components

-

High-reliability electronic parts

-

Automotive engine and transmission parts

-

Specialty materials processing and research projects

Technical Parameters

| Name / Parameter | Specification |

|---|---|

| Control Method | 15-inch Touch Screen |

| Effective Heating Zone Size (W×H×D) | 800 × 800 × 1200 mm |

| Long-Term Working Temperature | ≤ 700°C |

| Temperature Control Zones | 6 Zones |

| Heating Rate | 0–20°C/min (Adjustable) |

| Thermocouple Type | K Type |

| Temperature Control Accuracy | ±1℃ |

| Temperature Uniformity | ±5℃ |

| Heating Elements & Furnace Chamber | Nichrome Alloy Heating Belt + High-Purity Stainless Steel |

| Ultimate Vacuum | 7×10⁻⁴ Pa (Cold, Empty Furnace, After Baking) |

| Working Vacuum | 8×10⁻³ Pa (After Baking) |

| Vacuum Structure | Vacuum Chamber + Gate Valve Pump + Roots Pump + Diffusion Pump + Digital Vacuum Gauge + Stainless Steel Bellows + Pneumatic Baffle Valve |

Get Inquiry

Get Inquiry Send Email

Send Email