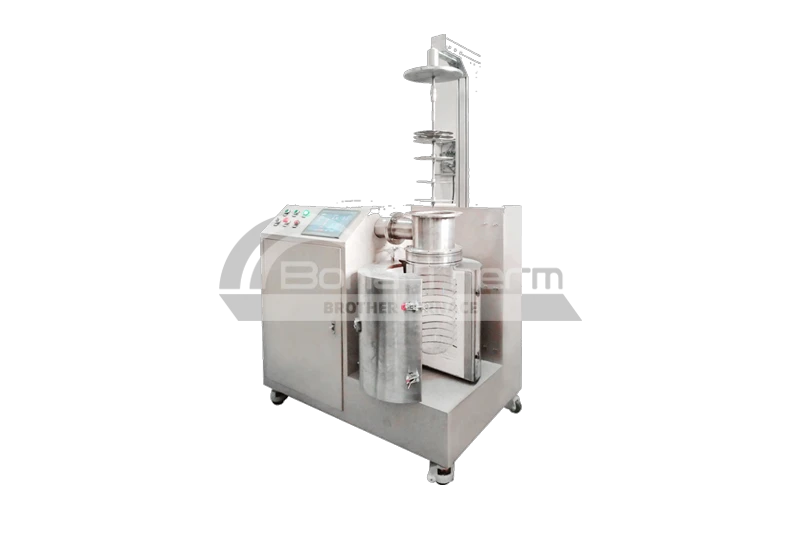

Introduction of Diamond Vacuum Brazing Furnace

The diamond vacuum brazing furnace is primarily used for brazing high-precision tools, such as diamond cutters, drills, and cutting tools. Due to the extreme hardness and unique properties of diamond materials, this furnace provides precise temperature control and an oxygen-free environment during the brazing process. It is widely used in industries like tool manufacturing, automotive parts processing, aerospace, mining, and construction. The furnace is especially suitable for brazing superhard materials onto metal substrates, such as bonding diamond to carbide or steel, ensuring a strong, wear-resistant interface.

Features of Diamond Vacuum Brazing Furnace

1. Vacuum Environment: Provides a high vacuum to reduce oxidation and carburization risks, ensuring the purity and strength of brazed materials.

2. Precise Temperature Control: Equipped with a high-precision temperature control system to regulate heating and cooling rates, ensuring consistent brazing quality.

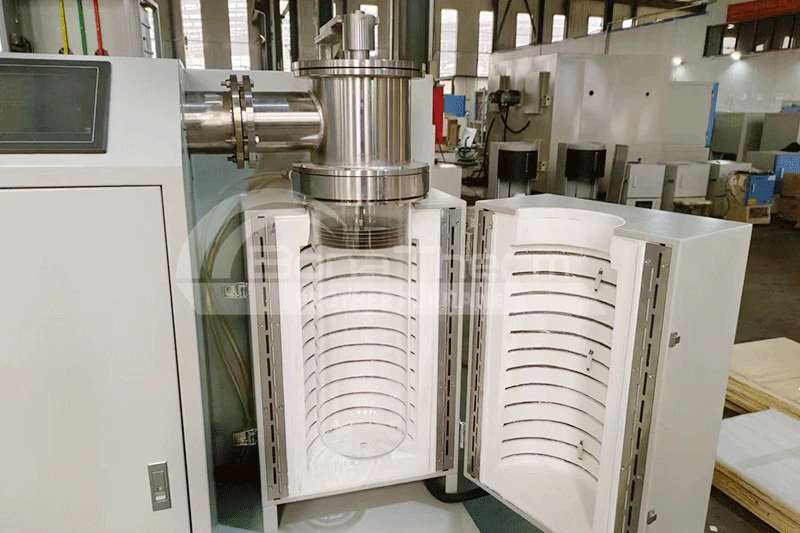

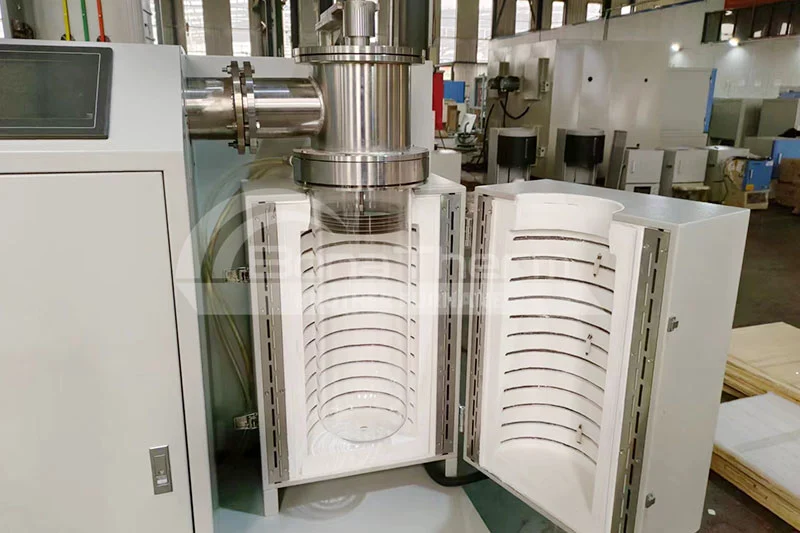

3. Uniform Heating: Advanced heating elements and thermal distribution design guarantee uniform temperatures across the workpiece surface, avoiding localized overheating or uneven cooling.

4. Energy Efficiency: Optimized design for reduced energy consumption, shortening heating time and increasing production efficiency.

5. Versatility: Accommodates brazing needs for various sizes and shapes of diamond tools, from small cutters to large industrial tools.

6. Maximum Operating Temperature of 1300°C: Capable of reaching up to 1300°C, meeting high-temperature brazing demands and ensuring strong bonding between diamond and metal substrates.

Applications

|  |

|  |

Get Inquiry

Get Inquiry Send Email

Send Email