Introduction

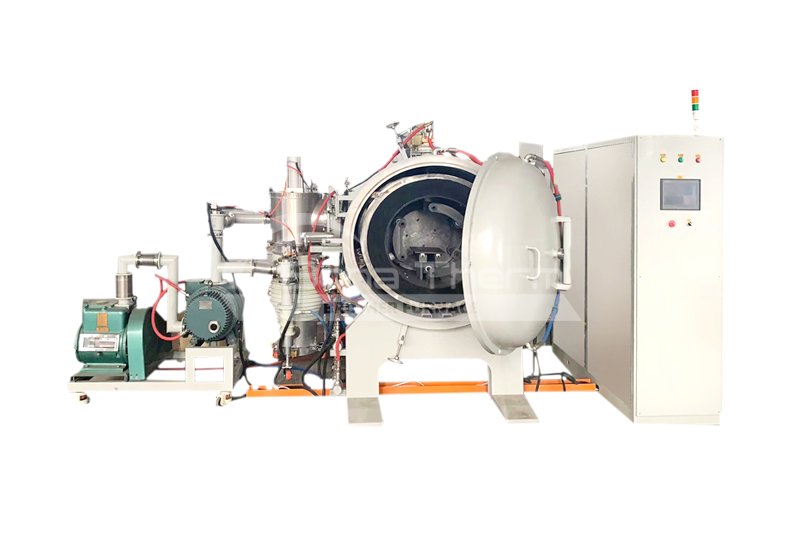

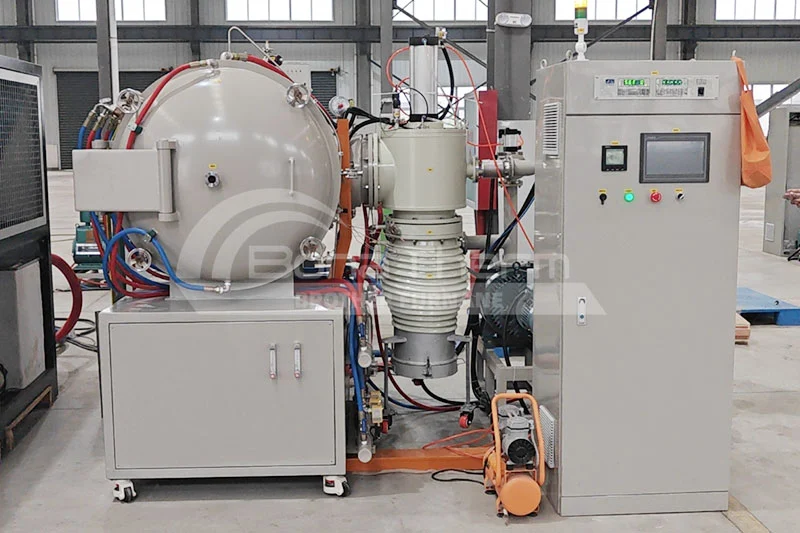

The typical components of vacuum annealing furnace include a heating furnace, vacuum system, control system, and safety system. Commonly used to process various metal materials, semiconductor materials, polymer materials, magnetic materials, etc. Usually, 750℃-1100℃ can be used for annealing treatment.

During the annealing process, the material to be treated is placed in a graphite furnace, which is then heated to the required temperature by a heating element. Next, a vacuum system removes oxygen and other gases from the furnace, creating an oxygen-free or low-oxygen environment to prevent oxidation or contamination of materials. The control system is responsible for monitoring and adjusting parameters such as temperature and pressure to ensure that the annealing process can achieve the expected results and ensure the safety of the operation.

Features

Using graphite as the heating element, the maximum temperature can reach 2400°C.

The insulation material uses imported soft and soft felt graphite to form a composite carbon fiber furnace.

The inner layer of the furnace shell is made of polished stainless steel, and the outer layer is made of carbon steel, with a double-layer water-cooled structure.

The human-machine interface adopts a high-definition touchscreen and has a built-in operating system developed by our company.

PLC automatic control system.

It adopts an advanced front and rear door opening design to facilitate customers to load and unload workpieces.

There is an observation window on the furnace shell to facilitate observation of the heating conditions in the furnace.

Use a tungsten-rhenium thermocouple and an infrared thermometer to measure temperature. The tungsten-rhenium thermocouple can enter and exit automatically.

Technical Parameters

model | Heating area (width*height*depth) ( mm ) | Working temperature (℃) | Power (kW) | Power supply ( V ) |

|---|---|---|---|---|

BR - 18GVF - 223 | 200*200*300 | 18 00 | 60 | 380 |

BR - 18GVF - 334 | 300*300*400 | 18 00 | 100 | 380 |

BR - 18GVF - 446 | 400*400*600 | 18 00 | 160 | 380 |

BR - 18GVF - 557 | 500*500*700 | 18 00 | 220 | 380 |

BR - 18GVF - 669 | 600*600*900 | 18 00 | 300 | 380 |

model | Heating area (width*height*depth) ( mm ) | Working temperature (℃) | Power (kW) | Power supply ( V ) |

|---|---|---|---|---|

BR - 22GVF - 223 | 200*200*300 | 2200 | 85 | 380 |

BR - 22GVF - 334 | 300*300*400 | 2200 | 150 | 380 |

BR - 22GVF - 446 | 400*400*600 | 2200 | 235 | 380 |

BR - 22GVF - 557 | 500*500*700 | 2200 | 315 | 380 |

BR - 22GVF - 669 | 600*600*900 | 2200 | 425 | 380 |

Get Inquiry

Get Inquiry Send Email

Send Email