Choose Your Vacuum Induction Melting Furnace Here

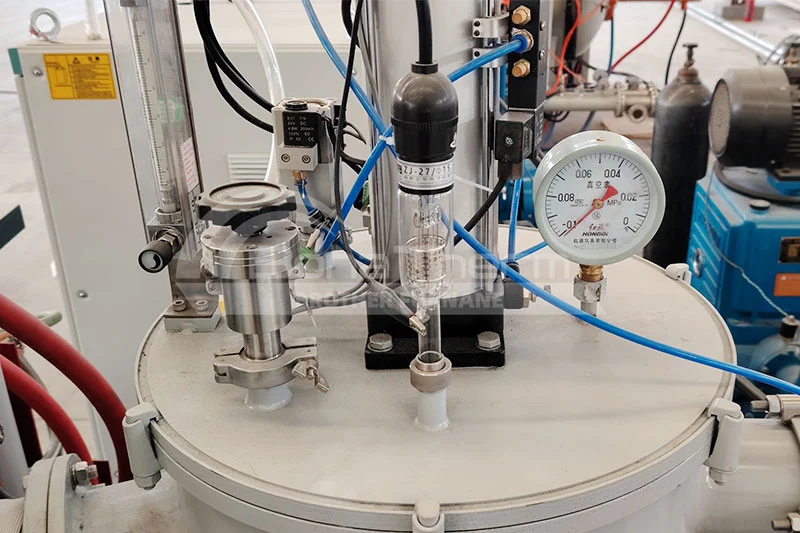

Detailed Display of Vacuum Brazing Furnace

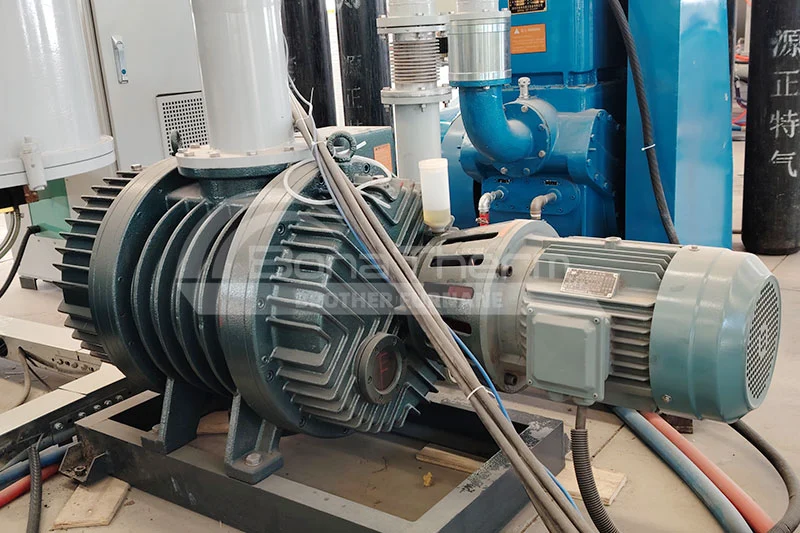

Vacuum induction melting is a special smelting technology that uses medium-frequency power to generate a strong magnetic field, forming eddy currents in a high-vacuum environment to heat and melt the solid metal.

Brother Furnace's vacuum induction melting furnace has the characteristics of fast heating, good heat preservation, high accuracy, and simple operation. It is widely used in industries and laboratories, such as aerospace, the automotive industry, electronics, semiconductors, etc. We export to customers all over the world. If you have any questions to discuss, please feel free to contact us

|  |  |

|  |  |

Unique Advantages Of Vacuum Induction Melting Furnace

- An almost unlimited range of materials can beused (base materials and brazing alloys);

- Minor distortions due to an even furnaceheating;

- Very good joining quality due to the vacuumatmosphere;

- High strength, even at high operatingtemperatures;

- Avoidance of fluxes;

- High reproducibility due to excellenttemperature uniformity and comfortablecontrol of modern furnace systems, including the process documentation;

- Possibility of a combined heat treatment(brazing and hardening);

- Hardening and annealing can be integrated into the process;

- Low environmentalimpact.

VIM Furnace Case Example

Material Type | Application Case Examples |

|---|---|

Stainless Steel | Precision micro-alloying control of 316L medical stainless steel |

Nickel-Based Superalloys | Homogenized melting of Inconel 718 |

Copper & Alloys | OFHC copper melting-casting |

Alloy Steels | Carbide homogenization study in H13 tool steel |

Ni-Co Alloys | CoCrWNi high-temperature wear-resistant alloy development |

NdFeB Rare Earth | Grain boundary diffusion for NdFeB magnets |

Non-Metal Sintering | SiC ceramic precursor sintering |

Investment Casting | Ti-Al alloy precision casting |

Brother Furnace's Qualification Certificate

Common Questions of Vacuum Induction Melting Furnace

-

What materials are suitable for melting with the vacuum induction melting furnace?

This equipment is suitable for melting a variety of metals, including precious metals, alloys, steel, and other special metals. It is particularly well-suited for materials that require high temperatures and high vacuum environments.

-

How is temperature stability ensured during the melting process?

Our vacuum induction melting furnace is equipped with programmed temperature control, allowing users to set heating or cooling curves based on process requirements. The equipment will automatically adjust the temperature to ensure stable operation.

-

Is the feeding process convenient?

The furnace is equipped with a standard metal feeder, which allows for easy addition of molten metal through a hand wheel. Additionally, an optional secondary feeding system is available for continuous feeding in a vacuum environment.

-

Is the equipment easy to maintain?

The furnace’s inductor is designed to be detachable, making maintenance and replacement easier. The furnace lid is equipped with an observation window, allowing for convenient monitoring of the internal conditions, ensuring long-term stable operation.

-

Is technical support provided after purchasing the equipment?

We offer comprehensive after-sales service and technical support, including equipment installation, commissioning, operator training, and ongoing technical assistance to ensure the efficient operation of your equipment.