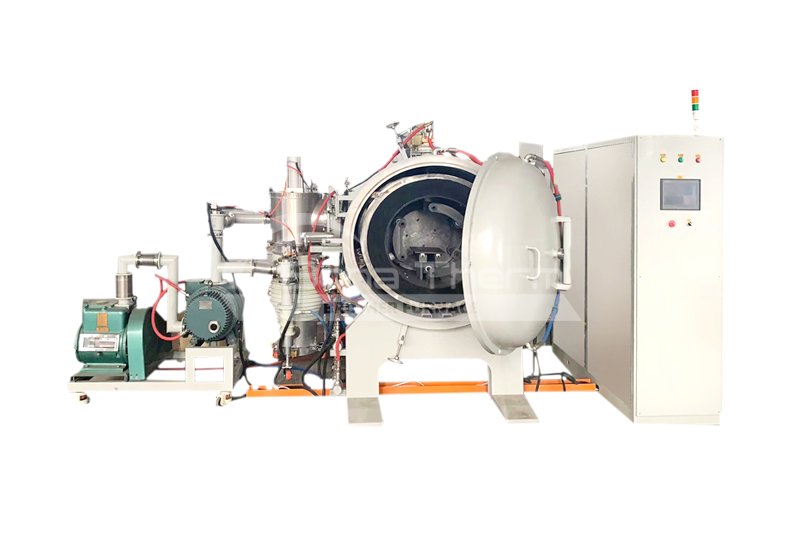

Introduction of Vertical Graphite Vacuum Furnace

The vertical graphite vacuum furnace is designed for precise high-temperature processing in a vertical orientation. It operates as a batch-type furnace and utilizes graphite tubes as heating elements, capable of reaching temperatures up to 2200°C. This furnace is ideal for sintering metal materials and inorganic non-metallic materials in a vacuum or protective atmosphere. Additionally, it can be used for roasting and purifying optical materials. Its vertical design facilitates efficient loading and unloading, while the high-purity graphite chamber ensures excellent thermal uniformity and high-temperature performance. Advanced temperature control systems and intelligent automation enhance its precision and reliability in controlled environments.

Features of Vertical Graphite Vacuum Furnace

Using graphite as the heating element, the maximum working temperature can reach 2400°C.

The inner layer of the furnace shell is made of polished stainless steel, and the outer layer is made of carbon steel, with a double-layer water-cooled structure.

There is an observation window on the furnace shell to facilitate observation of the heating conditions in the furnace.

The human-machine interface adopts a high-definition touchscreen and has a built-in operating system developed by our company.

PLC automatic control system.

Use a tungsten-rhenium thermocouple and infrared thermometer to measure temperature. The tungsten-rhenium thermocouple can enter and exit automatically.

Optional Accessories

Chiller

Graphite crucible

Technical Prameters

model | Studio size (diameter*height) ( mm ) | Working temperature (℃) | Power (kW) | Power supply ( V ) | Ultimate vacuum degree |

|---|---|---|---|---|---|

BR- 18 STV-40 | Φ1 6 0×160 | 1800 | 35 | 380 | 6.67×10-3Pa |

BR- 18 STV- 5 0 | Φ 20 0 × 30 0 | 1800 | 60 | 380 | |

BR-22STV-40 | Φ1 6 0×160 | 2200 | 50 | 380 | |

BR-22STV-50 | Φ 20 0 × 30 0 | 2200 | 90 | 380 |

Get Inquiry

Get Inquiry Send Email

Send Email