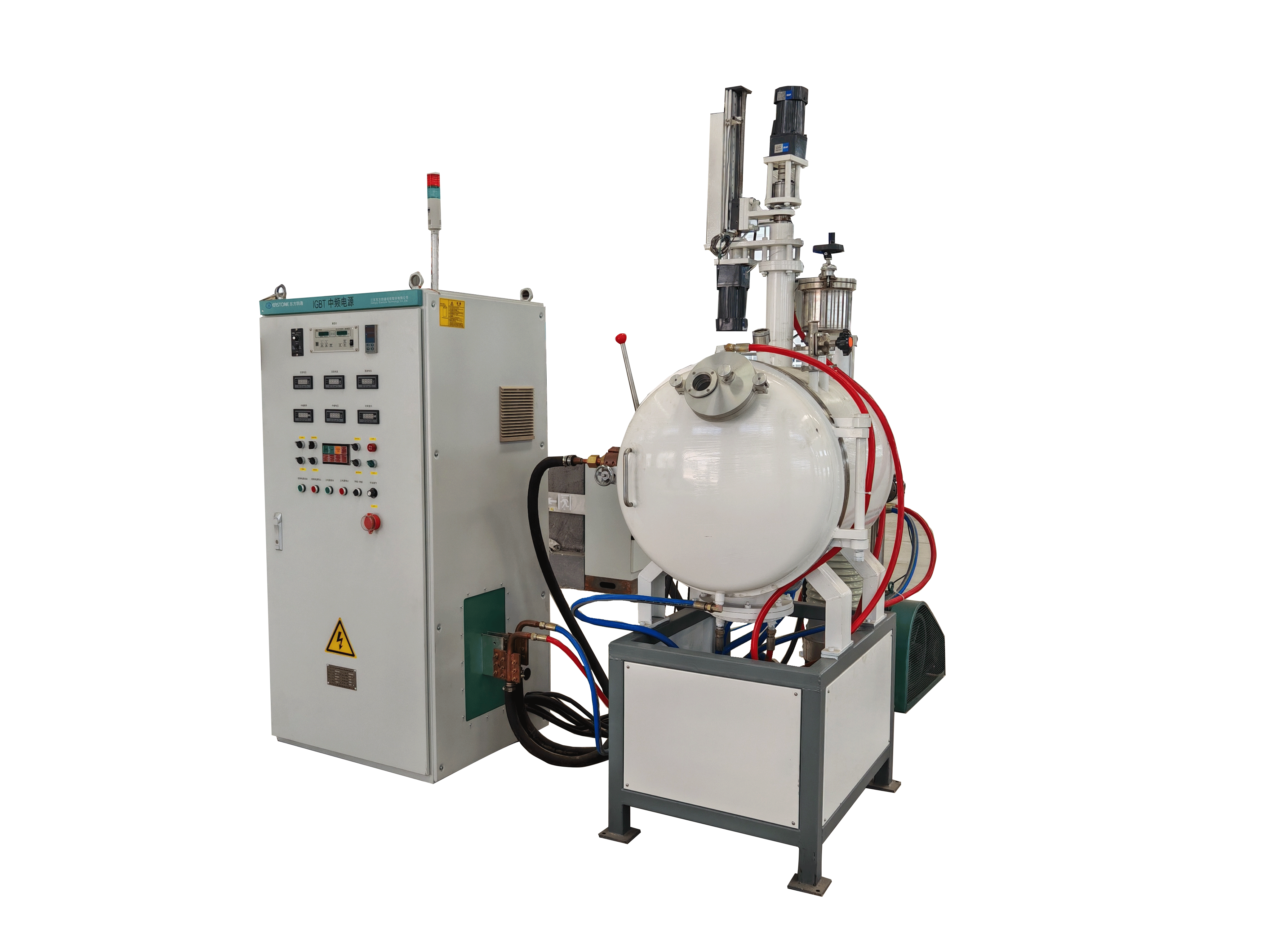

Introduction of 10kg Vacuum Induction Melting Furnace

The 10kg vacuum induction melting furnace from Brother Furnace is designed for melting high-purity metallic materials, with an operating temperature reaching up to 1500°C. It can complete high-temperature melting processes under vacuum or protective atmosphere conditions. Its advanced vacuum control and induction heating technology ensure the uniformity and purity of the materials, making it suitable for melting and casting various high-end metals, alloys, and specialty materials.

Structure of 10kg Vacuum Induction Melting Furnace

This furnace features an integrated design consisting of the furnace body, induction heating system, vacuum system, cooling system, and control system. The furnace chamber is made of high-quality refractory materials and includes built-in induction coils to ensure even heating. The vacuum system consists of an efficient vacuum pump and control valves, allowing for rapid vacuum evacuation and precise vacuum level control. The cooling system employs a closed-loop water cooling cycle to prevent equipment from overheating at high temperatures, extending the service life of the furnace body. The control system has a touchscreen and PLC programming, allowing users to easily set and monitor various parameters during the melting process.

Features of 10kg Vacuum Induction Melting Furnace

· High-Purity Environment: The vacuum and protective atmosphere technology effectively prevent oxidation and contamination, ensuring high purity of the metals.

· Precise Temperature Control: The combination of induction heating technology and an advanced temperature control system allows for rapid heating and stable temperature management.

· Quality Refractory Materials: The furnace interior uses high-temperature resistant materials, ensuring the stability of the equipment during long-term high-temperature operation.

· User-Friendly Operation: The integrated control panel and intelligent operation system make the melting process efficient and convenient.

· Flexible Application: Suitable for melting various metals and alloys, it can be used for research, experiments, and small-scale production needs.

Applications of 10kg Vacuum Induction Melting Furnace

The 10kg vacuum induction melting furnace is widely used in the research and development of metallic materials, aerospace, electronic materials, nuclear industry, and research laboratories. It is suitable for melting high-purity metals, specialty alloys, rare metals, and other materials that require processing in a vacuum environment.

Technical Parameters

model | Temperature (℃) | Power (kW) | Ultimate vacuum degree | Capacity ( kg ) |

|---|---|---|---|---|

BR- KZG-3 | 0-1750 | 35 | 5*10-3pa | 5 |

BR- KZG-5 | 0-1750 | 45 | 5*10-3pa | 5 |

BR- KZG-10 | 0-1750 | 65 | 6.7*10-3pa | 10 |

BR- KZG-25 | 0-1750 | 100 | 6.7*10-3pa | 25 |

BR- KZG-50 | 0-1750 | 160 | 6.7*10-3pa | 50 |

BR- KZG-100 | 0-1750 | 200 | 6.7*10-3pa | 100 |

Get Inquiry

Get Inquiry Send Email

Send Email