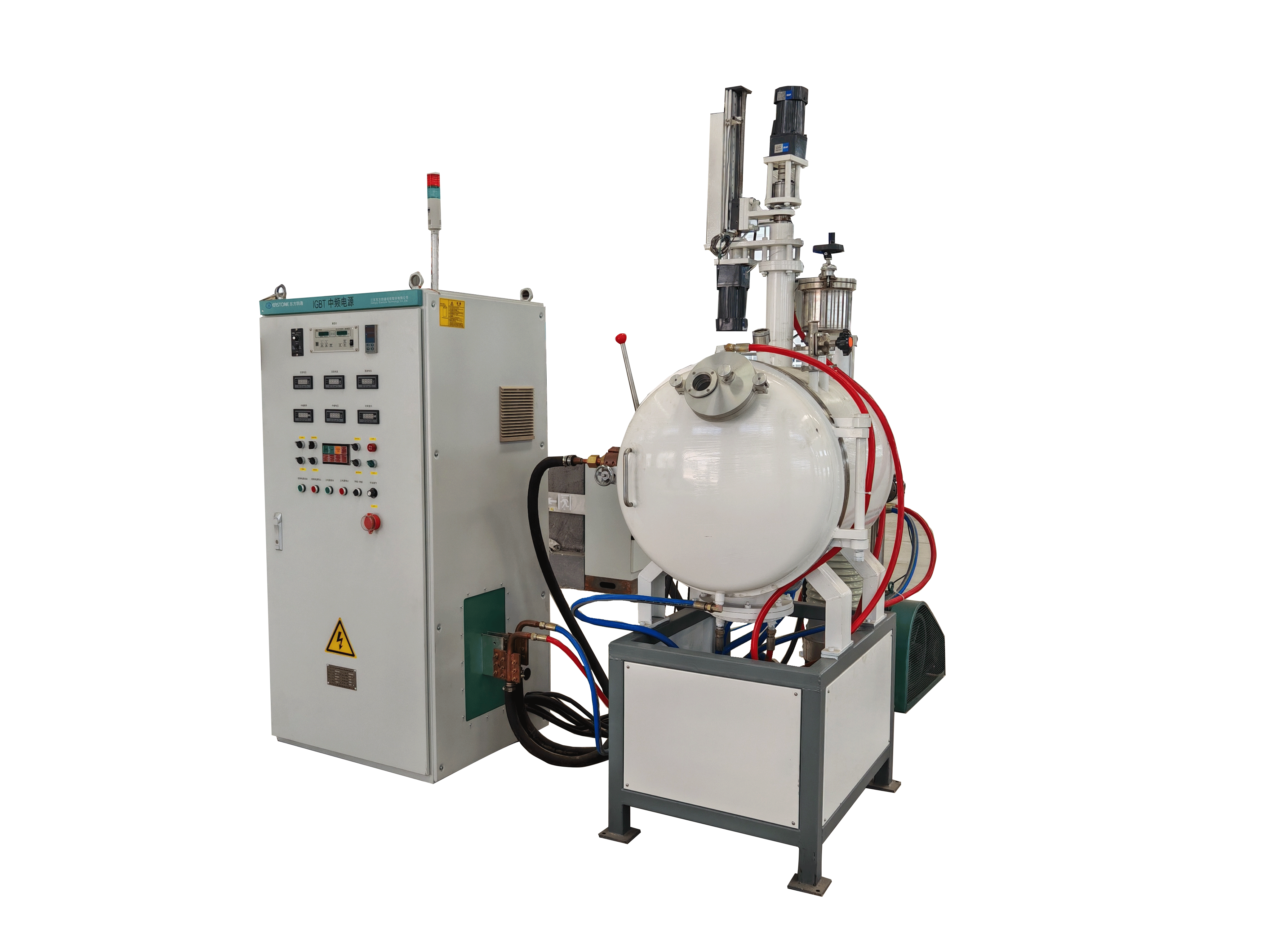

Introduction of 25 kg VIM Furnace

The 25kg Vacuum Induction Melting (VIM) Furnace is designed for precisely melting high-purity metals and alloys under vacuum or controlled atmosphere conditions. Equipped with advanced induction heating technology, the system ensures uniform temperature distribution and effective degassing, resulting in superior material quality.

The furnace can reach temperatures up to 2300°C, and customized designs are available to meet specific customer requirements.

Ideal for research institutions, specialized manufacturing, and high-end material development, this furnace offers consistent, reliable performance for demanding applications.

Applications

Hydrogen Energy:

Used in vacuum systems for the processing and handling of metals related to hydrogen energy, such as iron, manganese, and nickel.

Medical Field:

Applied in the production of medical-grade materials, including vacuum melting and refining of metals for human implants.

Zinc and Magnesium Alloy Melting:

Supports the vacuum melting and refining of zinc alloys and magnesium alloys for high-precision applications.

Steel Industry:

Utilized in the vacuum melting and refining of stainless steel and alloy steel to ensure superior material purity and performance.

Aluminum Alloy Melting and Ingot Casting:

Facilitates the vacuum melting and casting of aluminum alloys, enhancing material properties and minimizing impurities.

Features

- High Maximum Temperature: Supports melting operations up to 2300°C, suitable for a wide range of metals and alloys.

- Precise Temperature Control: Advanced induction heating system ensures rapid and uniform melting.

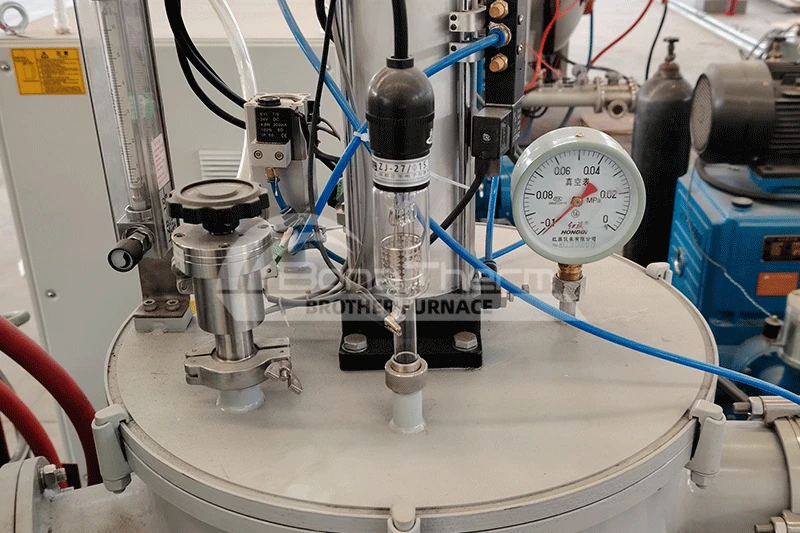

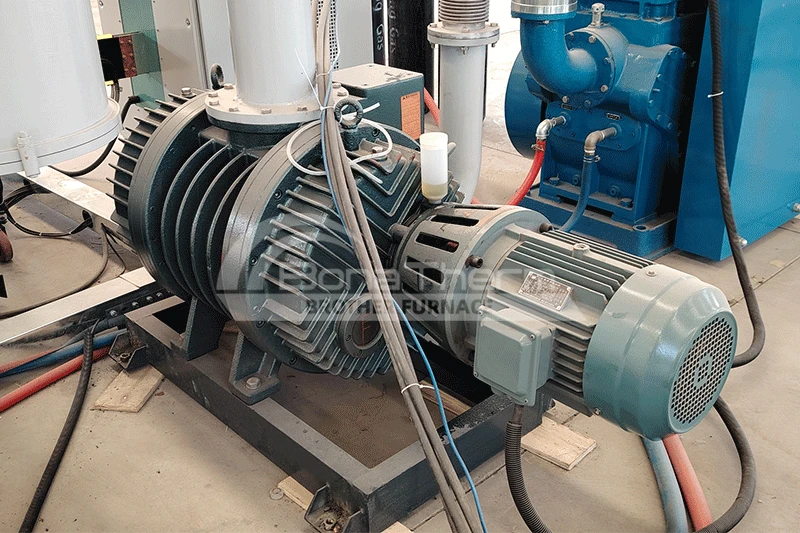

- High Vacuum Capability: Achieves high vacuum levels to minimize contamination and gas inclusions.

- Flexible Atmosphere Options: Supports operation under vacuum, inert gas, or reactive gas atmospheres.

- User-Friendly Interface: Integrated PLC control with touchscreen operation for easy monitoring and control.

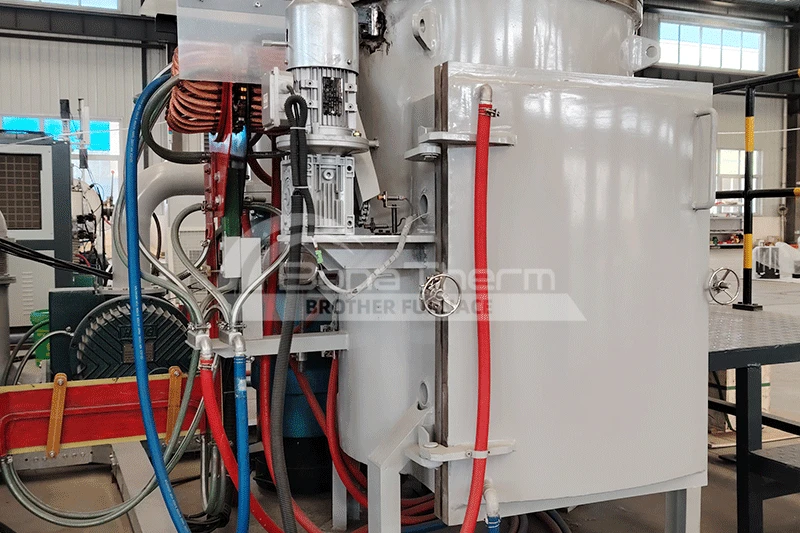

- Efficient Cooling System: Water-cooled induction coils and chamber for stable long-term operation.

- Customizable Solutions: Designs can be tailored to customer needs, including different crucible materials, mold types, and gas systems.

Technical Parameters

Model | Temperature(℃) | Power(kW) | Ultimate Vacuum(Pa) | Capacity(kg) |

|---|---|---|---|---|

BR-KZG-3 | 0-1750 | 35 | 5*10-3 | 5 |

BR-KZG-5 | 0-1750 | 45 | 5*10-3 | 5 |

BR-KZG-10 | 0-1750 | 65 | 6.7*10-3 | 10 |

BR-KZG-25 | 0-1750 | 100 | 6.7*10-3 | 25 |

BR-KZG-50 | 0-1750 | 160 | 6.7*10-3 | 50 |

BR-KZG-100 | 0-1750 | 200 | 6.7*10-3 | 100 |

Model | Loading Capacity(kg) | Rated Frequency(Hz) | Rated Power(kW) | Ultimate Vacuum(Pa) | Cooling Water(T/h) |

|---|---|---|---|---|---|

BR-RLL-10 | 10 | 3000 | 60 | 6x10-3 | 10 |

BR-RLL-25 | 25 | 2500 | 120 | 6x10-3 | 15 |

BR-RLL-50 | 50 | 2000 | 160 | 6x10-3 | 25 |

BR-RLL-100 | 100 | 2000 | 200 | 6x10-3 | 30 |

BR-RLL-200 | 200 | 1000 | 200 | 6x10-3 | 35 |

BR-RLL-300 | 300 | 800 | 250 | 6x10-3 | 40 |

BR-RLL-500 | 500 | 800 | 350 | 6x10-3 | 50 |

BR-RLL-1000 | 1000 | 800 | 400 | 6x10-3 | 70 |

Get Inquiry

Get Inquiry Send Email

Send Email