Bright Annealing of 316L Stainless Steel in Vacuum Furnace

BROTHER FURNACE

BROTHER FURNACE

2024-11-28 01:05

2024-11-28 01:05

Introduction

316L stainless steel is widely used in industries such as chemical, food, and pharmaceutical due to its exceptional corrosion resistance. Bright annealing is a key heat treatment process that further enhances its performance and durability. Typically performed in a vacuum furnace, this process improves the material’s surface quality, performance, and long-term reliability. This article explores the bright annealing process for 316L stainless steel, its benefits, and why the vacuum furnace is the ideal equipment for this treatment.

What is Bright Annealing?

Bright annealing is a heat treatment process that softens the material, relieves internal stress, and enhances corrosion resistance by heating the stainless steel in an oxygen-free environment. Unlike traditional annealing, bright annealing is done in a vacuum or controlled atmosphere furnace, preventing the formation of an oxide layer on the metal's surface. This is crucial for materials like 316L stainless steel, which require high surface quality and corrosion resistance.

Why Choose a Vacuum Furnace for Bright Annealing of 316L Stainless Steel?

A vacuum annealing furnace offers a controlled, clean environment that ensures efficient execution of the bright annealing process. Here are several key reasons why vacuum furnaces are ideal for this treatment:

Prevention of Oxidation

A major advantage of bright annealing is the prevention of oxidation. In traditional annealing, stainless steel is exposed to oxygen, leading to the formation of an oxide layer, which not only affects the appearance but also reduces corrosion resistance. By conducting the annealing process in a vacuum or inert gas atmosphere, the surface of 316L stainless steel remains free from oxidation, ensuring a clean and bright finish.

Enhanced Corrosion Resistance

316L stainless steel is known for its excellent corrosion resistance, particularly in chloride environments. The vacuum furnace's bright annealing process helps maintain this corrosion resistance by avoiding oxide layer formation. This ensures the material remains highly durable in harsh environments such as marine, chemical processing, and medical applications.

Improved Surface Quality

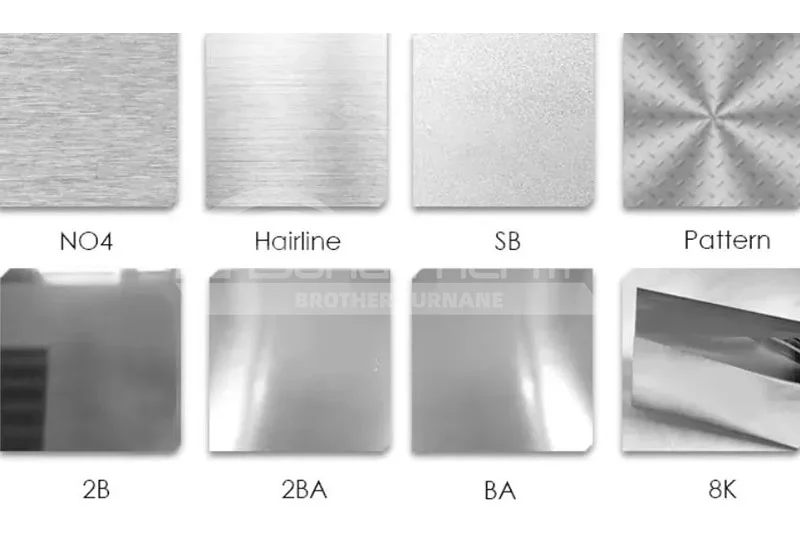

Compared to traditional annealing, bright annealing preserves the metal's smooth and bright surface without the formation of oxide layers. This is especially important for applications requiring high surface cleanliness and aesthetics, such as in the food and beverage industry, or high-end medical devices. The oxide-free surface also facilitates further processing like welding, coating, or surface finishing.

Precise Temperature Control

A vacuum furnace features precise temperature control systems, ensuring that the temperature during annealing stays within the optimal range, preventing overheating or underheating. This control is crucial for maintaining uniformity and mechanical properties of the material, avoiding unwanted phase changes or grain growth.

Reduced Decarburization

Decarburization is a common issue in heat treatment, where carbon loss from the surface can degrade the material's performance. Vacuum annealing significantly reduces decarburization, as the absence of oxygen and inert gas atmospheres prevents the material from reacting with oxygen, preserving the carbon content of the 316L stainless steel.

Applications of Bright Annealed 316L Stainless Steel

Medical Equipment & Implants: Due to its high purity and biocompatibility, 316L stainless steel is ideal for surgical tools, implants, and medical devices.

Food & Beverage Processing: Its bright, oxide-free surface makes it widely used in equipment and containers in the food industry, ensuring hygiene and cleanliness.

Chemical & Petrochemical Industries: 316L stainless steel's excellent chemical resistance makes it suitable for use in chemical pipelines, storage tanks, and reactors.

Aerospace & Marine Applications: The superior corrosion resistance and strength of 316L stainless steel make it well-suited for demanding aerospace and marine environments.

Brother Furnace’s Vacuum Annealing Furnace

Brother Furnace offers high-performance vacuum furnaces designed for precision annealing, catering to a wide range of applications. Various chamber materials are available, including molybdenum foil for high purity and stainless steel for cost-effectiveness. Brother Furnace ensures both quality and value. Our extensive experience in processing stainless steel, including over 100 successful case studies worldwide, positions us as a leading provider of vacuum annealing solutions. For those looking for the right furnace for 316L stainless steel, Brother Furnace offers tailored solutions with technical support.

For more information or to inquire about our vacuum furnaces, please feel free to contact us. We’re here to assist you with your material processing needs.