Introduction of Vacuum Debinding Sintering Furnace

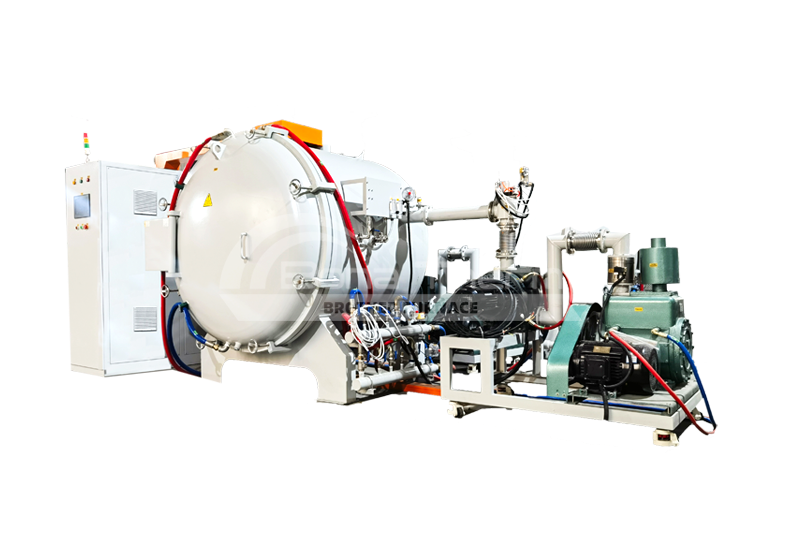

The vacuum debinding and sintering furnace is a type of vacuum furnace that incorporates debinding and sintering functions, widely utilized in powder metallurgy, ceramic sintering, and other processes requiring a high-temperature vacuum environment. The main components of the vacuum debinding and sintering furnace include the furnace body, heating elements, vacuum system, and control system, among others. Its working principle involves heating powder materials in a vacuum or inert gas environment to create strong bonding between powder particles, thereby achieving material densification.

Technical Parameters

model | Heating area (width*height*depth) ( mm ) | Processing capacity ( kgs ) | Power ( kW ) | Power supply ( V ) | gas |

|---|---|---|---|---|---|

BR-TZV-334 | 300*300*400 | 50 | 40 | 380 | Nitrogen, argon |

BR-TZV-446 | 400*400*600 | 100 | 80 | 380 | Nitrogen, argon |

BR-TZV-669 | 600*600*900 | 300 | 120 | 380 | Nitrogen, argon |

Improvements in the Vacuum Debinding and Sintering Furnace

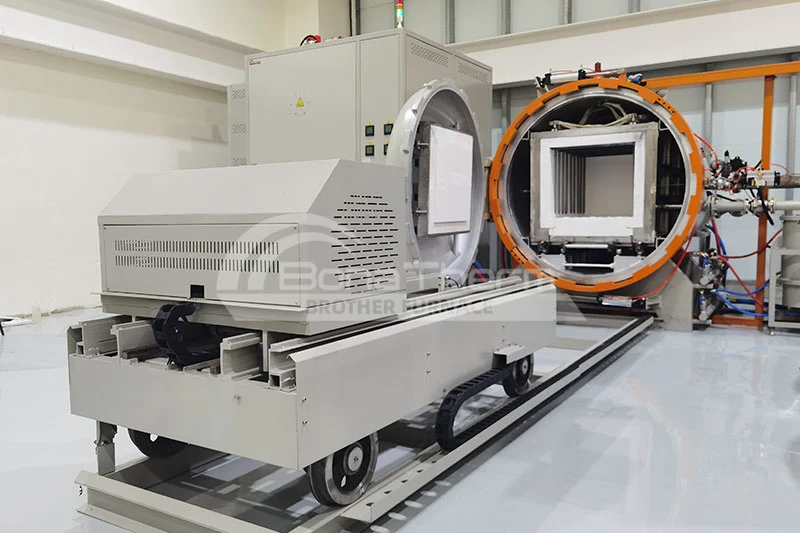

Installation of Square Sealed Box The square-sealed box enhances compactness and utilization in the furnace. This design optimizes space use and reduces gas and electricity consumption. Crucially, the efficient debing furnace prevents volatile gases from contaminating the furnace’s inner walls and insulation, ensuring safe gas discharge and maintaining a clean operating environment. | Introduction of Inert Gas Introducing inert gas (like nitrogen) into the furnace, along with pre-vacuuming, facilitates effective negative pressure degreasing. This method enhances the degreasing process's quality and efficiency, minimizes air reactions, and ensures material safety while reducing chemical contamination risks, thereby guaranteeing the final product’s purity. | Multi-layer Graphite Padding The multi-layer graphite pad design optimizes material loading and maximizes available furnace space. It enhances heating uniformity, thereby improving processing quality. This ensures that each material is treated in an optimal thermal environment, reducing heat loss and boosting overall operational efficiency. |

Advanced Heating Elements The heating system employs high-performance graphite rods with an insulation layer made from high-purity graphite composite carbon felt. This material selection ensures excellent thermal efficiency and stability at high temperatures, adapting to harsh conditions and improving the equipment’s overall performance and reliability. | High-Temperature Heating Capability The furnace can reach temperatures up to 1600℃, utilizing multi-zone temperature control. This feature enhances temperature uniformity, improving the consistency of the sintering process and ensuring stable quality in every batch. It supports various high-temperature material needs, providing extensive technical support for diverse applications. | Efficient Vacuum System The vacuum system combines mechanical pumps and Roots pumps, achieving 10 Pa in just 10 minutes. This rapid vacuuming capability ensures the necessary efficiency for the degreasing process, significantly enhancing product quality and reducing production cycles, thus improving overall production efficiency to meet modern industrial demands. |

|  |

Debinding and Sintering Process

1. Loading and Shaping We select suitable metal powders and binders and prepare green compacts through pressing or injection molding. | 2. Debinding Heating in the vacuum furnace to remove binders without oxidation. |

3. Sintering Maintaining at high temperatures to bond powder particles and form a dense structure. | 4. Cooling Gradual cooling to prevent internal stress and cracking, maintaining vacuum to prevent oxidation. |

Why Choose Brother Furnace as Your Vacuum Furnace Supplier?

Industry Experience

Brother Furnace has 20+ years of experience and technology accumulation in the field of vacuum furnaces and can provide reliable equipment and services.

High-Quality Equipment

The company offers high-performance, high-quality vacuum furnaces to meet various demanding process requirements.

Customized Solutions

Brother Furnace can provide customized vacuum furnace designs and solutions based on specific customer needs.

Energy Efficiency and Environmental Friendliness

Brother Furnace prioritizes energy efficiency in its designs, employing energy-saving technologies to achieve lower energy consumption and emissions, aligning with modern environmental standards.

For any inquiries or requirements related to vacuum heat treatment, feel free to contact Brother Furnace directly. Our dedicated engineers will guide you towards progress in your business.

Get Inquiry

Get Inquiry Send Email

Send Email