Introduction

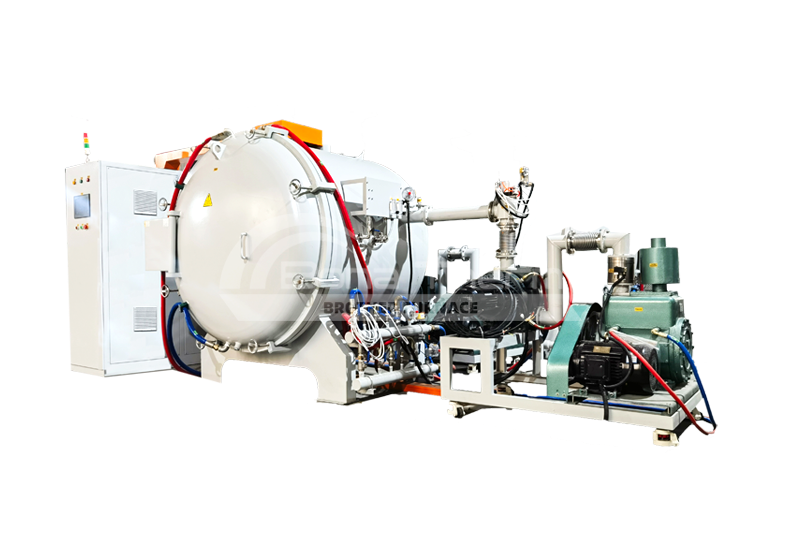

Lithium Hydroxide Vacuum Sintering Furnace, also known as the Horizontal Reaction Vacuum Sintering Furnace for Lithium Hydroxide or Lithium Hydroxide Vacuum Dehydration Sintering Furnace, is mainly used for the dehydration, sintering, and reduction of lithium hydroxide powder materials.

This equipment is specifically designed to carry out low-temperature dehydration of chemically bound water and the thermal decomposition of hydroxide groups, providing a controlled vacuum atmosphere ideal for high-purity processing.

Analysis of the Material Properties of Lithium Hydroxide

- Strong Alkalinity: Lithium hydroxide exhibits highly corrosive behavior at elevated temperatures, causing varying degrees of corrosion to stainless steel and most metallic materials.

- High Moisture Content & Irritant Gas Emission: The material contains significant water content and releases strongly irritating gases during processing.

- Substantial Dehydration at Low Temperature: Under a vacuum environment at 650°C to 700°C, anhydrous lithium hydroxide can lose approximately 48% of its total weight due to dehydration.

Technical Specifications

Model | Loading Dimensions | Working Temperature | Maximum Temperature | Ultimate Vacuum | Power Supply | Atmosphere Type |

|---|---|---|---|---|---|---|

BR-1100VF-4000 | 1000*1000*4000mm | 0-950℃ | 1100℃(<hours) | 20pa(Ultimate Vacuum) | 380V,50HZ,320KW | Ar/N2/H2 |

BR-1100VF-8816 | 800*800*1600mm | 0-950℃ | 1100℃(<hours) | 20pa(Ultimate Vacuum) | 380V,50HZ,90KW | Ar/N2/H2 |

Key Advantages of the Equipment

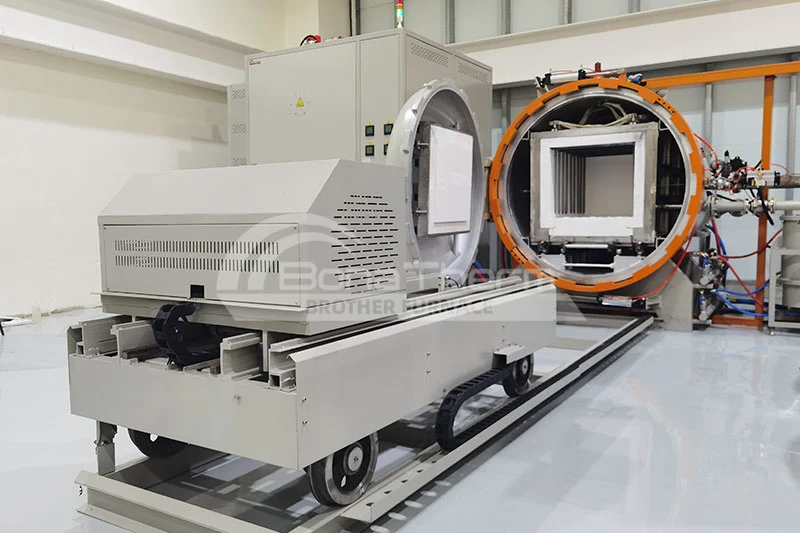

Horizontal Structure with Trolley Track Design

The furnace features a horizontal configuration with a trolley-based rail system. Both the furnace chamber and its base can be moved out of the main body, enabling easy loading, unloading, and routine maintenance.

High-Temperature Batch Calcination

Designed for batch calcination at high temperatures, the furnace ensures uniform heating of materials. This minimizes issues such as under-sintering, incomplete reaction, and over-sintering.

Multi-Point Temperature Measurement

The furnace is equipped with multiple temperature sensing points using specially customized thermocouples with ceramic alumina protective sheaths to resist alkaline corrosion and ensure accurate thermal monitoring.

Lightweight Refractory Lining with Vacuum Casting

The entire furnace lining is made from lightweight refractory materials and manufactured using advanced vacuum casting technology, resulting in high thermal efficiency.

Operating Temperature

The equipment's normal operating temperature does not exceed 1100°C, ensuring safety and stability during extended operation.

Corrosion-Resistant Furnace Chamber

The furnace chamber is specially engineered and reinforced to resist corrosion caused by the highly alkaline properties of lithium hydroxide materials.

Gas Atmosphere Control

The system allows for introducing various protective gas mixtures, enabling the formation of a clean and controlled atmosphere inside the furnace chamber.

PID Temperature Control

The furnace adopts PID (Proportional-Integral-Derivative) control mode for precise temperature regulation and stable thermal performance.

Applications

- Dehydration (Drying), Deoxidation, and Reduction Reactions of lithium hydroxide materials.

- Also suitable for oxidative treatment of catalyst carriers in the chemical industry and the sintering of inorganic salt powder materials.

- The system supports continuous rotary motion, ensuring optimal processing results through uniform thermal exposure.

Get Inquiry

Get Inquiry Send Email

Send Email