Introduction

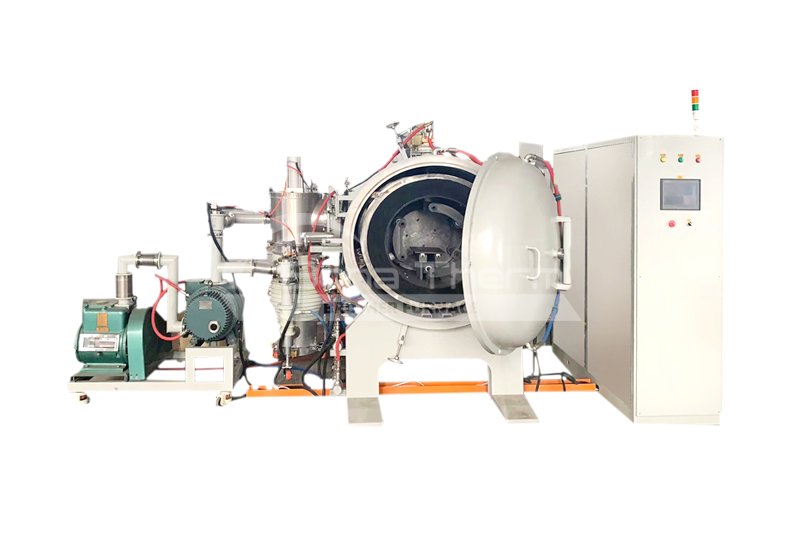

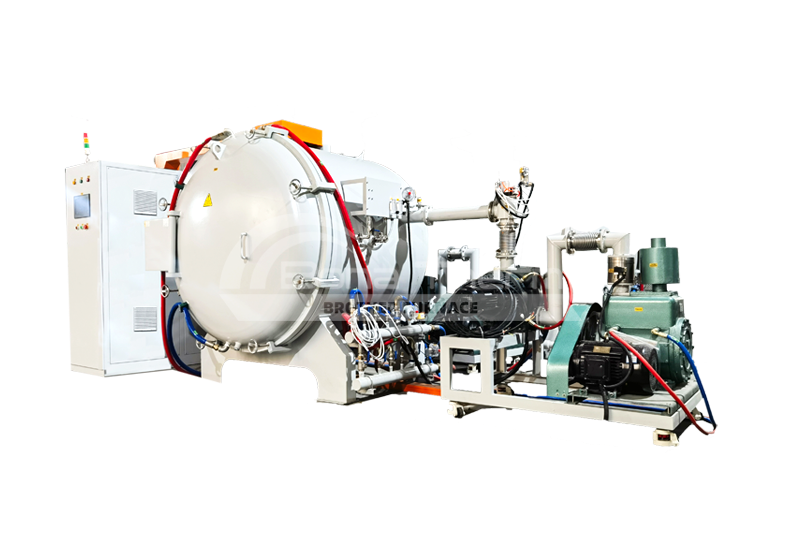

The vacuum tungsten wire furnace uses tungsten mesh heating, which is ultra-high temperature and clean and pollution-free. It is suitable for sintering high-purity ceramics into transparent ceramics, and sintering, degassing, and aging treatment of sapphire glass, zirconia, etc. under high vacuum. It is also suitable for use in pilot batch production by colleges universities and scientific research units.

|  |

|  |

Features

- Specially designed tungsten mesh heating and tungsten foil heat shield, the maximum temperature can reach 2400℃.

- The vacuum unit uses direct-connected vacuum pumps and molecular pumps, and the ultimate vacuum degree can reach 6x10-4Pa.

- The human-machine interface adopts a high-definition touchscreen and has a built-in operating system developed by our company.

- PLC automatic control system.

- It can be filled with nitrogen, argon, hydrogen, nitrogen-hydrogen mixed gas, and other gases.

Optional Accessories

- Chiller

- Tungsten crucible

Technical Parameter

model | Heating area (diameter*height) ( mm ) | Working temperature (℃) | Temperature field uniformity (℃) | Power (kW) | Ultimate vacuum degree |

|---|---|---|---|---|---|

BR-WSL-10 2 0 | Φ 100x 2 00 | 23 00 | ± 5 | 60 | 6x10-4Pa _ _ |

BR-WSL-20 4 0 | Φ 200x 4 00 | 23 00 | ± 5 | 160 | 6x10-4Pa _ _ |

BR-WSL-3050 | Φ 300x500 | 23 00 | ± 5 | 250 | 6x10-4Pa _ _ |

BR-WSL-4060 | Φ 400x600 | 23 00 | ± 5 | 340 | 6x10-4Pa _ _ |

Get Inquiry

Get Inquiry Send Email

Send Email