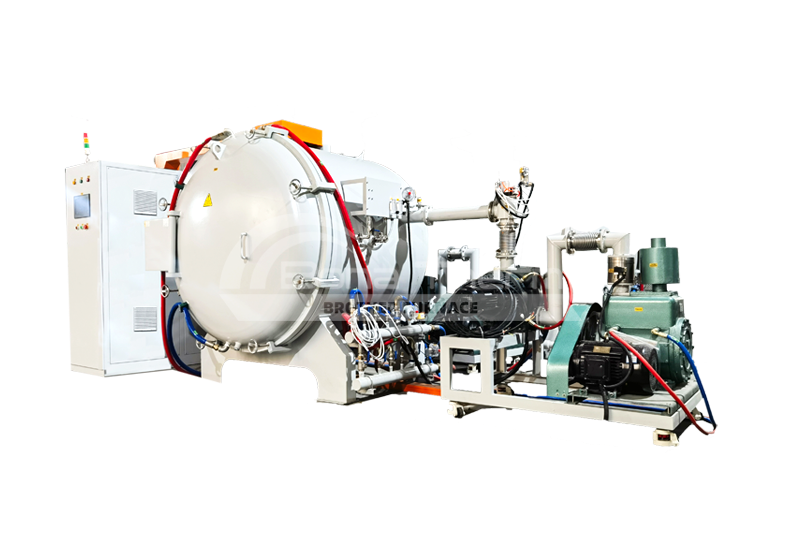

Introduction of Vacuum Atmosphere Sintering Furnace

The vacuum atmosphere sintering furnace is equipped with a vacuum system, which can pre-evacuate the furnace, fill it with deoxidized and dehydrated high-purity nitrogen, argon, nitrogen-hydrogen mixed gas, and other gases through a gas flow meter, and conduct product testing under atmosphere protection. Various heat treatments such as debinding, sintering, and annealing. During debinding, it can be equipped with a partial pressure aeration system, grease cooling, and a collection system.

|  |

Features

- Ceramic fiber furnace, silicon molybdenum rod heating, the maximum temperature can reach 1600 degrees.

- According to the length of the heating zone, multiple temperature zones can be controlled to ensure uniformity of the entire temperature field.

- Equipped with a two-stage rotary vane mechanical pump and Roots pump unit, the furnace can be quickly evacuated, and the ultimate vacuum degree can reach 7x10-1Pa.

- The human-machine interface adopts a high-definition touchscreen and has a built-in operating system developed by our company.

- PLC automatic control system.

- Special air path design. High-purity nitrogen undergoes deoxidation and dehydration treatment, enters the furnace body through the gas path, and is discharged through the exhaust port extending to the furnace, ensuring effective circulation of nitrogen in the furnace.

- It is designed with a trolley-type electric access to the furnace bottom, which can load and unload materials outside the furnace and facilitate maintenance of the furnace.

Optional Accessories

- Silicon nitride cartridge.

- Silicon nitride furnace floor lining.

Technical Parameter

model | Furnace size (width*height*depth) ( mm ) | Temperature (℃) | Number of temperature zones | Power (kW) | Power supply ( V ) |

|---|---|---|---|---|---|

BR- VAF -4412 | 400*400*1200 | 1600 | 3 | 60 | 380 |

BR- VAF -6616 | 600*600*1600 | 1600 | 3 | 105 | 380 |

BR- VAF - 6623 | 600*600*2300 | 1600 | 4 | 130 | 380 |

BR- VAF - 7730 | 740*740*3000 | 1600 | 4 | 200 | 380 |

Get Inquiry

Get Inquiry Send Email

Send Email