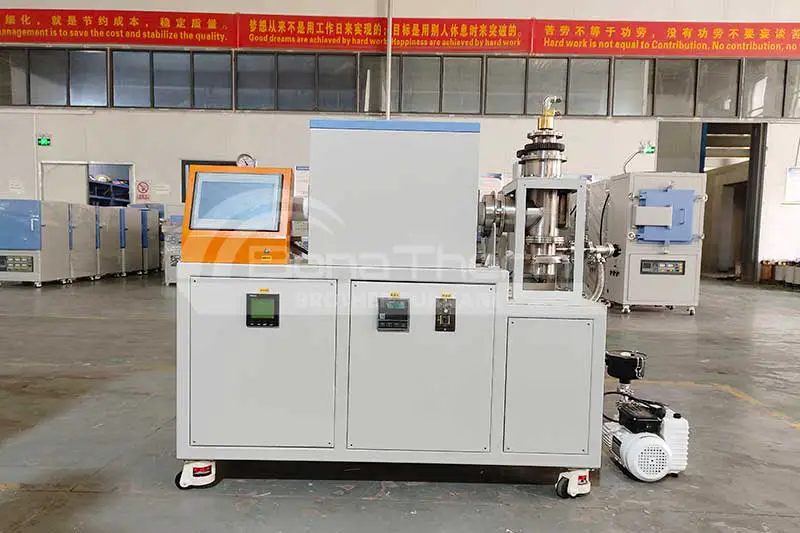

Introduction of PECVD Tube Furnace

Brother Furnace PECVD furnace is a thin film deposition equipment based on plasma chemical vapor deposition technology, which can deposit thin films on various materials, including metals, semiconductors, insulators, etc. It can be widely used in microelectronics, optoelectronics, flat panel displays, energy storage, and other fields.

|  |  |

Features

● Maximum temperature: 1200℃ (HRE resistance wire heating).

● Intelligent 50-segment programmable automatic control.

● Over-temperature protection function, automatically cuts off power when the temperature exceeds the allowed set value.

● Safety protection: Automatically cut off power when the furnace body leaks electricity.

● Furnace shell structure, double-layer air-cooling structure; surface temperature is lower than 50℃.

● The furnace adopts high-quality alumina polycrystalline fiber inorganic material formed by vacuum adsorption using Japanese technology, which has excellent thermal insulation performance.

● 304 stainless steel KF quick release sealing flange.

● Heating rate ≦20℃/min.

● Temperature control accuracy ±1℃.

● High film deposition rate: Radio frequency glow technology greatly improves the film deposition rate, with the deposition rate reaching 10Å/S.

● High uniformity over a large area: Advanced multi-point RF feed technology, special gas path distribution and heating technology are used to achieve a film uniformity index of 8%.

● High consistency: Using the advanced design concepts of the semiconductor industry, the deviation between each substrate deposited at one time is less than 2%.

● High process stability: Highly stable equipment ensures the continuity and stability of the process.

● The standard direct-connected vacuum pump has an ultimate vacuum degree of up to 10 Pa .

● Standard three-way mass flow meter .

● Plasma RF power supply: maximum RF power up to 500W, output frequency 13.56MHz±0.005%, input power supply 208-240VAC, single-phase 50/60Hz.

Optional accessories

● The vacuum system can be selected according to customer needs ( the highest vacuum degree can reach 7x10-4Pa, molecular pump vacuum system ).

● Gas mixing system and mass flow meter can be provided to meet the mixing of multiple gases and precise control of flow.

● HD touch screen.

Technical Parameters

model | Furnace tube diameter x heating zone length mm | Power ( kW ) | Maximum temperature Maximum temperature (℃) | RF power supply | gas control | Vacuum degree (Pa) | |

|---|---|---|---|---|---|---|---|

frequency | power | ||||||

BR-PECVD-60 | Φ 60×450 | 4 | 1200 | 13.56MHz±0.005% | 300-500W | 3 way | 10Pa/7x10-3 |

BR-PECVD-80 | Φ 80×450 | 5 | 1200 | 3 way | 10Pa/7x10-3 | ||

BR-PECVD-100 | Φ 100×450 | 7 | 1200 | 3 way | 10Pa/7x10-3 |

Get Inquiry

Get Inquiry Send Email

Send Email